|

Home

Failure Analysis

TIG Welding

MIG Welding

Flux Cored Welding

Stick Welding

SAW

Resistance Welding

Electron Beam Welding

Robotic Welding

Brazing & Soldering

Expert Witness

Experience

Fees

Links

Distortion

Discontinuities

Alloy Selection

Steel

Stainless

Steel

Aluminum

Section

IX of the ASME BPVC

ASME

P-Numbers

Structural

Welding

| |

Stick Welding

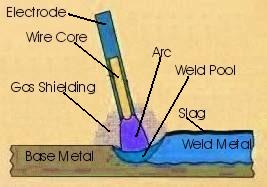

| Shielded Metal Arc Welding (SMAW) is frequently referred to as stick or

covered electrode welding. Stick welding is among the most widely used welding

processes.

The flux covering the electrode melts during

welding. This forms the gas and slag to shield the arc and molten weld

pool. The slag must be chipped off the weld bead after welding. The flux

also provides a method of adding scavengers, deoxidizers, and alloying elements

to the weld metal.

|

|

Stick Welding Benefits

- Equipment used is simple, inexpensive, and portable

- Electrode provides and regulates its own flux

- Lower sensitivity to wind and drafts than gas shielded welding

processes

- All position capability

Common Stick Welding Concerns

We can help optimize your welding process variables. Evaluate your

current welding parameters and techniques. Help eliminate common

welding problems and discontinuities such as those listed below:

-

- Undercut

- Incomplete fusion

- Porosity

- Slag Inclusions

- Cracks

-

Stick Welding Problems

- Arc Blow

- Arc Stability

- Excessive spatter

- Incorrect weld profile

- Rough surface

- Porosity

|

|

-

If your company is experiencing these or other welding problems you can retain

us to improve

your weld processing. Hire us to act as your welding

specialist.

Contact Information

- Telephone

-

407-880-4945 -------- (Consulting is only available for customers)

- FAX

-

- Postal address

-

- Electronic mail

- General Information:

bob@WeldingEngineer.com

Customer Support:

bob@WeldingEngineer.com

Webmaster:

-

|

![]()